一、组织机构及职位

XX电子有限公司XX Electronics CO., Ltd

总经理办公室 General manager’s office

企管部 Enterprise management department (EM)

行政部 Administration department (AD)

销售部 Sales department (SD)

财务部 Financial department (FD)

技术部 Technology department (TD)

物控部 Production material control department (PMC)

生产部 Production department(PD)

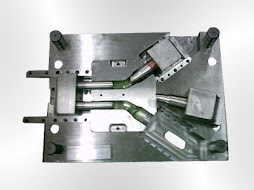

模具部 Mold manufacturing department, Tooling manufacturing department (TM)

品管部 Quality Assurance department (QA)

冲压车间 Stamp workshop, press workshop

注塑车间 injection workshop

装配车间 Assembly workshop

模具装配车间 Mold and die Assembly workshop

金属加工车间 metal machine workshop

电脉冲车间 Electric discharge process workshop

线切割车间 wire cutting process workshop

工磨车间 Grinding workshop

总经理 General manager (GM)

副总经理 Vice-general manager

经理 manager

董事长 president

副董事长 Vice-president

XX部门经理 Manager of XX department

主任、主管 supervisor

拉长 Line leader

组长 Foreman, forelady

秘书 secretary

文员 clerk

操作员 operator

助理 assistant

八.常用缩略词语

1、ES 工程规范 Engineering Specification

2、KCC 关键控制特性(GM)Key Control Characteristic

3、KPC 关键产品特性(GM)Key Product Characteristic

4、OEM 整车厂 Original Equipment Manufacturer

5、SC重要(特殊)特性 Significant(Special) Characteristic

6、ANOVA 方差分析法 Analysis of variance

7、CFT 多方论证小组 Cross function Team

8、DFMEA 设计失效模式及后果分析 Design Failure Mode and Effects Analysis

9、DOE 试验设计 Design of Experiment

10、DVP&R 设计验证计划和报告 Design verification Plan and Report

11、FTC 试生产能力 First Time Capability

12、GR&R 量具的重复性和再现性Gage Repeatability and Reproducibility

13、PFMEA 过程失效模式及后果分析Process Failure Mode and Effect Analysis

14、SFMEA 系统失效模式及后是分析 System Failure Mode and Effect Analysis

15、QSR 质量体系要求 Quality System Requirement

16、QFD 质量功能展开 Quality function Deployment

17、TGR 运行情况良好 Things Gone Right

18、TGW 运行情况不良 Things Gone Wrong

19、VE/VA 价值工程/价值分析 Value Engineering/Value Analysis

20、BOM 物料清单 Bill of Material

21、Cpk 稳定过程的能力指数 Capability for stable process

22、LCL 下控制限 Lower Control Limit

23、UCL 上控制限 Upper Control Limit

24、LSL 工程规范下限 Lower Specification Limit

25、USL 工程规范上限 Upper Specification Limit

26、Ppk 性能指数 The performance index

27、MRB 物料评审 Material Review Board

28、PSW 零件提交保证书 Part Submission Warrant

29、X(—)--R图 均值一极差图 Average-Range Chart

30、SRPC 供方要求产品更改 Supplier Request for Product Change

31、SREA 供方工程批准的要求 Supplier Request for Engineering Approval

32、IAA 临时批准授权 Interim Approval Authorization

33、AAR 外观件批准报告 Appearance Approval Report

34、PTR 试生产(报告) Production Trial Run (Report)

35、DCP尺寸控制计划(动态控制计划)Dimension Control Plan (Dynamic Control Plan)

37、防错(POKA-YOKE)Mistake Proofing

五、生产

注塑机 injection machine

冲床 Punch machine

混料机 blender mixer

尼龙 nylon

黄铜 brass

青铜 bronze

紫(纯)铜 copper

料斗 hopper

麻点 pit

配料 compounding

涂层 coating

飞边 flash

预热 preheating

再生料 reworked material

再生塑料 reworked plastics

工艺设计 process design

紧急停止 emergency stop

延时 time delay

六.物控

保质期shelf life

ABC分类法ABC Classification

反常需求Abnormal Demand

措施信息Action Message

活动报告标志Action-report-flag

基于活动的成本核算Activity-based Costing (ABC)

实际能力Actual Capacity

实际成本Actual Costs

调整现有库存量Adjust-on-hand

已分配量Allocation

替代工序Alternative Routine

装配订单Assembly Order

装配零件表Assembly Parts List

装配Assembly

计划自动重排Automatic Rescheduling

可达到库存Available Inventory

可用材料Available Material

达到库存Available Stock

可利用工时Available Work

可签约量Available-to-promise

平均库存Average Inventory

欠交订单Back Order

倒序计划Back Scheduling

倒冲法Back flush

未完成订单Backlog

现有库存余额Balance-on-hand Inventory

批号Batch Number

批量生产Batch Production

标杆瞄准Benchmarking

工时清单Bill of Labor

提货单Bill of Lading

物料清单Bill of Material

分库Branch Warehouse

经营规划Business Plan

采购员Buyer

能力管理Capacity Management

能力需求计划Capacity Requirements Planning (CRP)

保管费率Carrying Cost Rate

保管费Carrying Cost

单元式制造Cellular Manufacturing

修改批量日期Change Lot Date

修改工序Change Route

修改产品结构Change Structure

检查点Check Point

闭环物料需求计划Closed Loop MRP

通用工序标识Common Route ID

计算机集成制造Computer-integrated Manufacturing (CIM)

配置代码Configuration Code

约束管理/约束理论Constraints Management/Theory of Constraints (TOC)

依成本的材料清单Costed Bill of Material

急需零件Critical Part

累计提前期Cumulative Lead Time

现有运转时间Current Run Hour

现有运转数量Current Run Quantity

周期盘点Cycle Counting

调整日期Date Adjust

有效日期Date Available

修改日期Date Changed

结束日期Date Closed

截止日期Date Due

生产日期Date in Produced

库存调整日期Date Inventory Adjust

作废日期D ate Obsolete

收到日期Date Received

交付日期Date Released

需求日期Date Required

发货日期Date to Pull

空负荷Dead Load

需求管理Demand Management

需求Demand

实际能力Demonstrated Capacity

非独立需求Dependent Demand

直接增减库存处理法Direct-deduct Inventory Transaction Processing

发料单Disbursement List

派工单Dispatch List

分销资源计划Distribution Resource Planning (DRP)

鼓-缓冲-绳子Drum-buffer-rope

经济订货批量Economic Order Quantity (EOQ)

工程变更生效日期Engineering Change Effect Date

工程变更生效单Engineering Change Effect Work Order

工程停止日期Engineering Stop Date

例外控制Exception Control

呆滞材料分析Excess Material Analysis

急送代码Expedite Code

加工订单Fabrication Order

补足欠交Fill Backorder

总装提前期Final Assembly Lead Time

确认的计划订单Firm Planned Order

固定订货批量F ixed Order Quantity

集中预测Focus Forecasting

完全跟踪Full Pegging

通用生产管理原则Generally Accepted Manufacturing Practices

毛需求Gross Requirements

在制品库存In Process Inventory

独立需求Independent Demand

投入/产出控制Input/ Output Control

检验标识Inspection ID

厂际需求Interplant Demand

库存周转率Inventory Carry Rate

仓库库位类型Inventory Location Type

库存周转次数Inventory Turnover

发送订单Issue Order

项目记录Item Record

物料项目Item

加工车间Job Shop

准时制生产Just-in-time (JIT)

看板Kanban

人工工时Labor Hour

最后运输日期Last Shipment Date

提前期Lead Time

层Level

负荷量Load Leveling

负荷报告Load Report

负荷Load

仓位代码Location Code

仓位备注Location Remarks

仓位状况Location Status

按需订货Lot for Lot

批量标识Lot ID

批量编号Lot Number

批量Lot Size

低位码Low Level Code

机器能力Machine Capacity

机器加载Machine Loading

外购或自制决策Make or Buy Decision

面向订单生产的产品Make-to-order Product

面向库存生产的产品Make-to-stock Product

制造周期时间Manufacturing Cycle Time

制造资源计划Manufacturing Resource Planning (MRP II)

主生产计划Master Production Schedule (MPS)

物料成本Material Cost

物料发送和接收Material Issues and Receipts

物料需求计划Material Requirements Planning (MRP)

登陆标志MPS Book Flag MPS

多重仓位Multiple Location

净改变式MRP N et Change MRP

净需求Net Requirements

新仓位New Location

新组件New Parent

新仓库New Warehouse

不活动报告No Action Report

现有库存量On-hand Balance

未结订单Open Order

订单输入Order Entry

订货点Order Point

订货方针Order Policy

订货承诺Order Promising

订货备注Order Remarks

双亲Parent

零件清单Part Bills

零件批次Part Lot

零件编号Part Number

零件Part

反查Pegging

领料单Picking List

领料/提货Picking

计划订单Planned Order

后减库存处理法Post-deduct Inventory Transaction Processing

前减库存处理法Pre-deduct Inventory Transaction Processing

发票价格Price Invoice

采购订单价格Price Purchase Order

优先计划Priority Planning

产品控制Product Control

产品线Production Line

生产规划编制Production Planning

产品率Production Rate

产品结构树Production Tree

预计可用库存Projected Available Balance

采购订单跟踪Purchase Order Tracking

已分配量Quantity Allocation

仓位数量Quantity At Location

欠交数量Quantity Backorder

完成数量Quantity Completion

需求量Quantity Demand

毛需求量Quantity Gross

进货数量Quantity In

排队时间Queue Time

队列Queue

重生成式MRP Regenerated MRP

重排假设Rescheduling Assumption

资源需求计划Resource Requirements Planning

粗能力计划Rough-cut Capacity Planning

工艺路线Routing

安全库存量Safety Stock

保险期Safety Time

预计入库量Scheduled Receipt

残料率Scrap Factor

发送零件Send Part

维修件Service Parts

发货地址Ship Address

发货单联系人Ship Contact

发货零件Ship Date

发货单Ship Order

工厂日历Shop Calendar

车间作业管理Shop Floor Control

损耗系数Shrinkage Factor

标准产品成本Standard Product Cost

标准机器设置工时Standard Set Up Hour

标准单位运转工时Standard Unit Run Hour

标准工资率Standard Wage Rate

状况代码Status Code

库存控制Stores Control

建议工作单Suggested Work Order

约束理论Theory of Constraints (TOC)

时间段Time Bucket

时界Time Fence

单位成本Unit Cost

采购计划员Vendor Scheduler

采购计划法Vendor Scheduling

工作中心能力Work Center Capacity

工作中心Work Center

在制品Work in Process

工作令跟踪Work Order Tracking

工作令Work Order

工作进度安排Work Scheduling

零库存Zero Inventories

经济订货批量=Squat(2*年订货量*平均一次订货准备所发生成本/每件存货的年储存成本)

美国生产和库存控制协会APICS,American Production & Inventory Control Society

七.QS-9000中的术语

APQP Advanced Product Quality Planning and Control Plan,产品质量先期策划和控制计划

PPAP Production Part Approval Process,生产件批准程序

FMEA Potential Failure Mode and Effects Analysis,潜在失效模式及后果分析

MSA Measure System Analysis,测量系统分析

SPC Statistical Process Control,统计过程控制

审核 Audit

能力 Capability

能力指数 Capability Indices

控制计划 Control Plans

纠正措施 Corrective Action

文件 Documentation

作业指导书 Job Instruction, work instruction

不合格品 Nonconformance

不合格 Nonconformity

每百万零件不合格数 Defective Parts Per Million, DPPM

预防措施 Preventive Action

程序Procedures

过程流程图 Process Flow Diagram, Process Flow Chart

质量手册Quality Manual

质量计划 Quality Plan

质量策划 Quality Planning

质量记录Quality Records

原始数据Raw Data

反应计划Reaction Plan

返修Repair。

返工Rework

现场Site

分承包方Subcontractors

产品product

质量quality

质量要求quality requirement

顾客满意customer satisfaction

质量管理体系quality management system

质量方针quality policy

质量目标quality objective

质量管理quality management

质量控制quality control

质量保证quality assurance

组织organization

顾客customer

供方supplier

过程process

服务service

设计与开发design and development:

特性characteristic

可追溯性trace ability

合格conformity

缺陷defect

纠正correction

让步concession

放行release

报废scrap

规范specification

检验inspection

试验test

验证verification

评审review

测量measurement

计数型数据Attributes Data

普通原因Common Cause

单值Individual

均值Mean

随机抽样Random Sampling

极差Range

特殊原因Special Cause

稳定性Stability

子组Subgroup

计量型数据variables Data

变差variation

固有变差Inherent variation

总变差Total variation

偏倚Bias

重复性Repeatability

再现性Reproducibility

稳定性Stability

线性Linearity

分辨率Resolution

过程更改Process change

质量功能展开QFD

过程特殊特性Special Process Characteristic

产品特殊特性Special Product Characteristic

外观项目Appearance Item

初始过程能力Preliminary Process Capability

材料清单Bill of Material

设计确认Design Validation

设计验证Design Verification

顾客的呼声Voice of the Customer

过程的呼声Voice of the Process

二、产品

连接器 connector

端子 terminal

条型连接器 bar connector

阴连接器 Housing

阳连接器 wafer

线束 wire harness

间距 space

额定电压 rated voltage

额定电流 rated current

接触电阻 contact resistance

绝缘电阻 insulation resistance

超声波焊接 ultrasonic welding

耐压 withstand voltage

针 pin

物料编号 part number

导线 wire

基体金属 Base metal

电缆夹 cable clamp

倒角 chamfer

接触面积 contact area

接触件安装孔 contact cavity

接触长度 contact length

接触件电镀层 contact plating

接触压力 contact pressure

接触件中心距 contact space

接触簧片 contact spring

插孔 socket contact

法兰、凸缘 Flange

界面间隙 interfacial gap

键 Key

键槽 keyway

过渡段 ramp

屏蔽套 shielding

定位基准 Datum reference

扁平电缆f lat cable ,Ribbon cable

柔性印刷电线 Flexible printed wiring

多层印制电路 Multilayer printed circuit

焊盘 pad

图形 pattern

间距 pitch

负极 Negative pole

正极 positive pole

回流 Reflow

原理图 Schematic diagram

单面板 single sided board

双面板 Two-sided board,Double-sided board

表面安装 surface Mounting

翘曲 warp, bow

波峰焊 wave soldering

编织层 braid

同轴电缆 coaxial cable

电介质 dielectric

电缆中导线的头数 ends

外部干扰 external interference

填充物 filler

护套 jacket

比重 specific gravity

电阻的温度系数 Temperature coefficient of resistance

三、模具

塑料模具 mould of plastics

注塑模具 injection mould

冲压模具 die

模架 mould base

定模座板 Top clamping plate

Top plate

Fixed clamp plate

水口推板 stripper plate

A板 A plate

B板 B plate

支承板 support plate

方铁 spacer plate

底针板 ejector plate

面针板 ejector retainer plate

回针 Return pin

导柱 Guide pin

有托导套 Shoulder Guide bush

直导套 Straight Guide bush

动模座板 Bottom clamp plate

Moving clamp plate

基准线 datum line

基准面 datum plan

型芯固定板 core-retainer plate

凸模固定板 punch-retainer plate

顶针 ejector pin

单腔模具 single cavity mould

多腔模具 multi-cavity mould

多浇口 multi-gating

浇口 gate

缺料 starving

排气 breathing

光泽 gloss

合模力 mould clamping force

锁模力 mould locking force

挤出 extrusion

开裂 crack

循环时间 cycle time

老化 aging

螺杆 screw

麻点 pit

嵌件 insert

活动镶件 movable insert

起垩 chalking

浇注系统 feed system

主流道 sprue

分流道 runner

浇口 gate

直浇口 direct gate , sprue gate

轮辐浇口 spoke gate , spider gate

点浇口 pin-point gate

测浇口 edge gate

潜伏浇口 submarine gate , tunnel gate

料穴 cold-slug well

浇口套 sprue bush

流道板 runner plate

排飞槽 vent

分型线(面) parting line

定模 stationary mould,Fixed mould

动模 movable mould, movable half

上模 upper mould, upper half

下模 lower mould, lower half

型腔 cavity

凹模 cavity plate,cavity block

拼块 split

定位销 dowel

定位销孔 dowel hole

型芯 core

斜销 angle pin, finger cam

滑块 slide

滑块导板 slide guide strip

楔紧块 heel block, wedge lock

拉料杆 sprue puller

定位环 locating ring

冷却通 cooling channel

脱模斜度 draft

滑动型芯 slide core

螺纹型芯 threaded core

热流道模具 hot-runner mould

绝热流道模 insulated runner mould

熔合纹 weld line (flow line)

三板式模具 three plate mould

脱模 ejection

换模腔模具 interchangeable cavity mould

脱模剂 release agent

注射能力 shot capacity

注射速率 injection rate

注射压力 injection pressure

差色剂 colorant

保压时间 holdup time

闭模时间 closing time

定型装置 sizing system

阴模 female mould,cavity block

阳模 male mould

电加工设备 Electron Discharge Machining

数控加工中心 CNC machine center

万能铁床 Universal milling machine

卧式刨床 Horizontal planer

车床 Engine lathe

平面磨床 Surface grinding machine

去磁机 Demagnetization machine

万能摇臂钻床 Universal radial movable driller

立式钻床 Vertical driller

超声波清洗机 Ultrasonic clearing machine

四、品管

SPC statistic process control

品管保证 Quality Assurance

品管控制 Quality control

来料检验 IQC Incoming quality control

巡检IPQC In-process quality control

校对 calibration

动态试验 dynamic test

环境试验 Environmental test

非破坏性试验 non-destructive test

光泽 gloss

击穿电压(dielectric) breakdown voltage

拉伸强度 tensile strength

冷热骤变试验 thermal shock test

环境试验炉 Environmental chamber

盐雾实验 salt spray test

绝缘电阻测试验仪 Insulating resistance meter

内应力 internal stress

疲劳 fatigue

蠕变 creep

试样 specimen

撕裂强度 tear strength

缩痕 shrink mark, sink mark

耐久性 durability

抽样 sampling

样品数量 sample size

AQL Acceptable Quality level

批量 lot size

抽样计划 sampling plan

OC曲线 operation curve

试验顺序 sequence of tests

环境温度 ambient temperature

可焊性 solderability

阻燃性flame resistance

china mold builder

china plastic injection mold designing and making

We are designers and moldmakers for plastic and rubber industry in China. Located in Changan ,dong guan ,we are able to make your mold project and also injection on our factory. If you have any idea on a project please contact us. We have good solutions and nice prices. For contact please mail me: orientmold@gmail.com. I will be very pleased to help you.

Blog Archive

-

▼

2008

(79)

-

▼

October

(41)

- 工程图常用英语

- 塑胶模具成形不良用语英汉对照

- 阀门零部件英汉术语对照

- UG术语中英对照表CAM部分

- 射出成形關聯用語

- 模具常用刀具與工作法用語

- 各種沖模加工關連用語

- 沖壓機械及周邊關連用語

- 鍛鑄造關連用語

- 模具加工方法

- 模具行业常用日语

- 外向型塑料制品企业常用的英语词汇

- 常用塑料原料的中日文对照大全表

- 塑料注塑成型不良的中日文对照大全表

- AutoCAD机械制图英语词汇

- 注塑技术员用英语大全

- 模具软件英文用语

- 螺丝产品名称中英文对照

- 常用塑料的中英文缩略语大全

- 铸造常用词中英文对照及简释

- 模具工序/工艺中英文对照表

- 塑料模具常识--注塑(

- 塑料模具的抛光方法

- 双料注塑

- 常用塑料缩水率

- 模具知识

- 广东各地模具术语

- 广东模具术语

- mold english translation

- mold english 2

- mold english

- 模具模架

- 模具材料

- 怎样找客户

- 常用塑料手册

- crazy english 100

- mold construction

- 各国公共邮箱

- 世界各国公司名称后缀/各国域名后缀

- 外贸技巧

- Japanese Mold glossary 模具日文术语

-

▼

October

(41)

About Me

Labels

- english (11)

- SEO (9)

- 英语 (9)

- 模具术语 (6)

- 模具用语 (6)

- 模具技术 (5)

- mold english (4)

- 外贸技巧 (4)

- 商务 (3)

- 国语 (3)

- 时事 (3)

- 模具 (3)

- mold (2)

- mouldglossary (2)

- 冲压模具用语 (2)

- 模具商务 (2)

- 模具行情 (2)

- 模具零件 (2)

- mold business (1)

- mold language (1)

- mold structure (1)

- മmold language (1)

- മൌല്ദ് mold manufacturer (1)

- 励志 (1)

- 塑胶原料 (1)

- 外贸搜索 (1)

- 外贸营销 (1)

- 模具刀具 (1)

- 模具加工 (1)

- 模具日语 (1)

- 模具材料 (1)

- 模具英语 (1)

- 模具设计 (1)

- 模具钢材 (1)

- 注塑 (1)

- 注塑原料 (1)

- 注塑材料 (1)

- 注塑模具用语 (1)

- 营销 (1)

- 铸造模 (1)

- 铸造模具 (1)

home appliance mould

precision plastic mould

receiver box mold

electronic mould

Followers

daily goods mold

hand tool mold

cleaner piper mould

OEM molding

plastic molding part

du material mould

double injection mold

cup mold

connector mold

cap mold

AP plastic mould

big mould

auto mould